Tire Valve Stem Cap Missing

Pre-Trip Inspection – External Cab Steering Box and Hoses Check that the steering box is mounted securely and is not leaking. Check for damage to power steering hoses and power steering fluid leaks. Check that connecting links, arms, and rods from the steering box to the wheels are not worn and cracked. Check that the joints and sockets are not loose or worn and that there are no missing nuts, bolts, or cotter keys. Check for shifted, cracked, broken, or even missing leaf springs. Check for broken and distorted coil springs. If equipped, check the air ride suspension for damage and leaks. Look for cracked or broken spring hangers, missing or damaged bushings, and broken, loose, or missing bolts, U-bolts or other axle mounting parts. Confirm that the shock absorbers are secure and that there are no leaks. Look for missing, loose or broken parts. The angle between the adjuster arm and push rod should be not less than 90 degrees when the brakes are applied and when the brakes are released a little over 90 degrees.

When pulled by hand, the brake rod should not move more than one inch with the brakes released. Check that brake chambers are not dented, cracked, or leaking and that they are mounted securely. Brake Hoses and Lines Check for worn, cracked or leaking hoses, lines, and couplings. Drum Brake or Rotor Check for dents, cracks or holes, and loose or missing bolts. Brake linings and pads should not be worn thin.

Blue Staffy Puppies For Sale Newcastle Where visible, check that a reasonable amount of brake lining is showing.

Loll Outdoor Furniture Sale Check for damaged or bent rims.

Motorcycle Lift Table EdmontonRims cannot have welding repairs. For every tire, check: Tread depth: need a minimum tread depth of 4/32 on steering axle tires, 2/32 on all other tires.

Tire condition: Check that tread is evenly worn and without cuts or damage to tread or sidewalls. Valve caps and stems should not be missing, broken, or damaged. Tire inflation: Check for proper inflation with a tire gauge or by striking tires with a mallet. Hub Oil Seals, Axle Seals Check that hub oil/grease seals and axle seals are not leaking. Check for any missing lug nuts, cracks, distortions, and for signs of looseness such as rust trails or shiny threads. Check for cracked or distorted bolt holes. Spacers should not be bent, damaged, or rusted through. Spacers should be centered evenly. Check doors for any damage and that they open and close properly. Hinges should be secure with seals intact. Mirrors and mirror brackets should be mounted securely. Check for secure tanks, tight caps, and that the tanks or lines don’t leak. Battery and Battery Box Check to see that batteries are secure, for tight cable connections, and that cell caps are present.

Check for signs of excessive corrosion. Battery box and cover/door must be secure. The drive shaft should not be bent or cracked. Couplings should be secure. Check system for rust or carbon soot as they are signs of damage or leaks. System should be secure and connected tightly. Check the longitudinal frame members, cross members, box, and floor for cracks, broken welds, holes or other damage. If equipped with mud flaps or splash guards, check that they are mounted securely and not damaged. Doors, Ties and Lifts Doors and hinges must open, close, and latch properly from the outside, and should not be damaged. Check that any ties, straps, chains, and binders are secure. If equipped with a cargo lift, it must be fully retracted and latched securely, and should not be leaking, damaged or missing any parts. Air and Electric Lines Check that electrical lines and air hoses are not cut, chafed, spliced, or worn, the steel braid should not show through its outer lining.

Make sure the lines and hoses are not tangled or dragging against tractor parts. Make sure the catwalk is securely bolted to tractor frame. Check for loose or missing mounting brackets, clamps, bolts, or nuts. The fifth wheel and the slide mounting must be solidly attached. Other types of coupling systems should be inspected for missing or broken components. Check that the locking jaws fully close around the kingpin. On other types of coupling systems the locking mechanism should not have missing or broken parts and should lock securely. The platform structure supporting the fifth wheel skid plate should be free of cracks or breaks. Release Arm (fifth wheel) If equipped with a release arm, check that it engaged and that the safety latch is in place. Kingpin, Apron and Gap The kingpin should not be bent. The visible part of the apron should not be bent, cracked, or broken. The trailer should be laying flat on the fifth wheel skid plate without any gap.

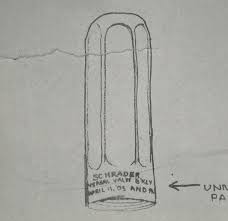

Locking Pins (fifth wheel) Locking pins should be fully engaged. The fifth wheel should be positioned so the tractor frame will not strike the landing gear or the tractor. The Five (5) Components of the Pre-Trip Inspection Cab Check and Engine Start Study and Training Guides Download the 5 Components of the Pre-Trip Inspection Pre-Trip Inspection Study Guide... learn exactly what you need to pass the exam! California DMV Commercial Driver License Handbook Pre-Trip Inspection Study Guide... know exactly what you need to pass the exam! Learn more... order a High Quality Pre-Trip Inspection Training DVD for just $45.00. See a sample online. Applause from our Students Watch a video testimonial and read about how happy GSF's students are with our classroom instruction, driver training and comprehensive service. Become a Professional Driver Get your license to drive a commercial vehicle. Schrader valve components (from left to right) the valve core closed (top) and open (bottom), the order of assembly, end view of stem without core and with core (top) and stem with dust cap on (bottom)

Schrader valve advertisement, National Geographic April, 1921. Unusually tall Schrader valve stem with valve core A Schrader valve advertisement, Horseless Age, 1918. The Schrader valve (also called American valve[1]) is a type of pneumatic tire valve used on virtually every motor vehicle in the world today. The Schrader company, for which it was named, was founded in 1844 by August Schrader. The original Schrader valve design was patented in the United States in 1893. The Schrader valve consists of a valve stem into which a valve core is threaded, and is used on virtually all automobile tires and motorcycle tires and most wider rimmed bicycle tires. The valve core is a poppet valve assisted by a spring. In addition to tube and tubeless tires, Schrader valves of varying diameters are used on many refrigeration and air conditioning systems to allow servicing, including recharging with refrigerant; by plumbers conducting leak-down pressure tests on pipe installations;

as a bleeding and test port on the fuel rail of some fuel injected engines; on bicycle air shock absorbers to allow adjustment of air pressure according to riders weight; and in the buoyancy compensator (BC) inflators of SCUBA systems where the ability to easily disconnect an air hose (even underwater) without the loss of tank air is critical. Schrader valves are also widely used in high-pressure hydraulic systems on aircraft.[] Many domestic fire extinguishers use an internal valve identical to a Schrader valve, but with a lever on top to enable quick release of the pressurized content. A Schrader valve consists of an externally threaded hollow cylindrical metal tube, typically of brass. In the center of the exterior end is a metal pin pointing along the axis of the tube; the pin's end is approximately flush with the end of the valve body. Generally, all Schrader valves used on tires have threads and bodies of a single standard size at the exterior end, so caps and tools generally are universal for the valves on all common applications.

The core of the valve can be removed or tightened with a tool. A new development is Schrader valve stems with integrated transmitters for tire pressure monitoring systems (TPMS). A valve cap is important on a Schrader valve because if one is not fitted, dirt and water can enter the outside of the valve, potentially jamming it or contaminating the sealing surfaces and causing a leak. Rock salt and other chemical de-icers used in the winter are especially damaging for the brass components in the Schrader valve. Some valve caps have a rubber-washer seal (or a synthetic-rubber-washer seal) inside to help make a hermetic seal (airtight seal). Such a rubber-washer-sealing-type cap also helps prevent air from escaping from a slightly leaking valve. In addition, the rubber washer prevents the cap from loosening and falling off due to vibrations and hence being lost, by acting as a cushion between the cap and the valve stem and in this way damping the vibrations. Whereas Schrader valves are almost universal on car tires, bicycle tubes have Dunlop, Schrader or Presta valves.

Both the Schrader and the Presta types are good at sealing high pressures. Their chief differences are that Schrader valves are larger and have springs that close the valve except when the pin is depressed. Schrader valves are used in a wide variety of compressed gas and pressurized liquid applications. Presta valve stems are 6 mm diameter, whereas Schrader valve stems for bicycle tires are 8 mm, thus requiring a larger diameter hole in a bicycle rim. While not a concern on wider bike rims, it will weaken a narrow wheel rim, precluding their use on (road) racing bicycles. Another disadvantage of the Schrader is that the air chuck must depress the spring-loaded pin before air can flow during inflation, whereas the Presta valve relies solely on internal air pressure to keep it shut. This means that some air is lost while attaching and detaching pumps to Schrader valves, although this is usually minimal (most of the air which makes the "whooshing" noise when the pump is removed comes from the compressed air in the tube between the pump body and the attachment end, not the tire via the momentarily-open Schrader valve).